Friday, September 18, 2020

Second Hand Stitching Machine - vssewingmachine

Used Sewing Machines For Sale - vssewingmachine

Used Sewing Machines For Sale - vssewingmachine

Buy Second Hand Sewing Machine Online - vssewingmachine

Buy Second Hand Sewing Machine Online - vssewingmachine

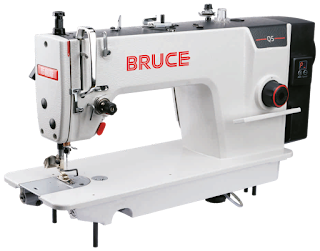

VS Sewing Machine, Buy Second Hand Sewing Machine Online offers you with the Top selling brands along with all its Sewing

Machines models in the Industry. You can get the recommendations over

here with the industry experts. Also we serves you best Pre-Selling as

well as the Post Selling Services. Read More

THe smart factory is a futuristic production paradigm that transforms ICT(Information and communication technology) into a new smart/green/urban production system by integrating the existing traditional industrial production system.[1-2] Industry 4.0 proposed by DFKI, is defined as the 4th industrial revolution based on Internet-of-Things(IoT), cyber-physical systems(CPS), and Internet-of-Services(IoS). [3-6] In the textile industry, the smart factory is a factory based on the CPS that incorporates ICT and IoT technology into the existing production system.[7-8] In order to build a smart factory between textile and apparel streams, the connectivity of the CPS should be strengthened.

This study focuses on the construction of a CPS system to realize a smart factory by deriving three representative processes (fabric, dyeing, sewing) among textile streams. Figure 1 shows the data flow of CPS based inter-stream smart manufacturing system. The rectangle marked with read lines represents the part for detecting and controlling the sewer data for the smart of the sewing process which is the core of this research and View More

extile stream smart factory CPS implementation can only be done by linking together the ordering system, design automation system, product information management system, production information integration system and production equipment automation.[6] Fig. 2 shows the interlinkage of high-throughput, high-productivity production systems that minimize plant-to-plant collaboration and prototype production to accommodate small-volume and multi-stream requirements between streams, and can be instantly produced on demand

https://www.vssewingmachine.com/

https://goo.gl/maps/U7becHNt6xCt3LeLA

Used 2nd Hand Sewing Machine - vssewingmachine

Used 2nd Hand Sewing Machine - vssewingmachine

Second Hand Sewing Machines - vssewingmachine

Second Hand Sewing Machines - vssewingmachine

VS Sewing Machine, Second Hand Sewing Machines offers you with the Top selling brands along with all its Sewing Machines models in the Industry. You can get the recommendations over here with the industry experts. Also we serves you best Pre-Selling as well as the Post Selling Services.