Designing System Singer FM3321 - VS SewingMachine

Automatic sewing machine has been broadly used in the household and industry. It provides a fast way to apply the pattern sewing on the cloth. Designer utilizes the computer software to create the new patter and convert it into the stitch coordinates to form the sewing path that can be read by the automatic sewing machine. This whole process results in the broidery CAD software system. In the conventional way of designing the sewing path, people place the pattern on a board with the grid covering on the surface of the board and record every stitch coordinate manually. The collection of each stitch coordinate forms the sewing path that can be input into the sewing machine. Nowadays, the implementation of the broidery CAD system provides a convenient way to develop the new sewing pattern SINGER FM984

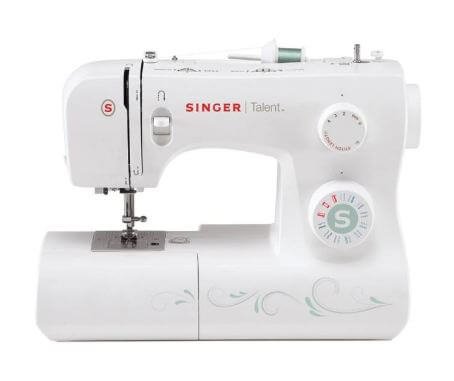

The SINGER 3321 Talent sewing machine is perfect for budding fashionistas.

With easy threading, top drop-in bobbin, and automatic needle

threader, set-up is simple and frustration-free. Features include 21

stitch patterns, and adjustable stitch length and width. Variable needle

positions make clothing construction and other creative projects not

only possible, but fun and easy.Singer FM3229

Automatic Needle Threader

Easily threads the needle without frustration or eye strain.

Top Drop-In Bobbin

Easier to thread and track thread usage than a front-load bobbin.

Heavy Duty Metal Frame

The internal skeleton of the sewing machine. This rigid support holds

all the mechanisms in perfect alignment for perfect sewing and

durability.

Variable Needle Positions

Needle position can be changed for individual projects, such as inserting zippers or cording and top stitching.

Adjustable Stitch Length and Width

Keep seams strong and prevent bunching on any type of fabric–personalize stitch length and width with just a turn of a dial.

Free Arm

Provides professional results by offering easy access to cuffs, collars, pant hems and other difficult-to-reach areas.

SINGER is Sewing Made Easy Standard Accessories Included

All Purpose/General Presser Foot, Zipper Foot, Buttonhole Foot,

Button Sewing Foot, Seam Ripper/Lint Brush, Edge/Quilting Guide,

Needles, Bobbins, Spool Holder, Screwdriver, Darning Plate, Spool Pin,

Spool Pin Felt, Power Cord/Foot Control, Instruction Manual, Soft-Sided

Dust Cover Click Here

https://www.vssewingmachine.com/

https://g.page/VS-sewing-perambur?share

https://goo.gl/maps/fvkeRgVTfQwtj9G47