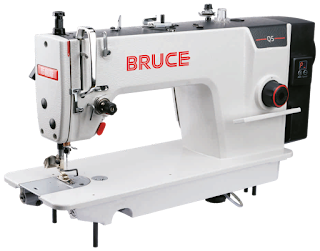

Sewing Machine Showroom in Perambur, Chennai - VS SewingMachine

VS Sewing Machine, Sewing Machine Showroom in Perambur, Chennai offers you with the Top selling brands along with all its Sewing Machines models in the Industry. You can get the recommendations over here with the industry experts. Also we serves you best Pre-Selling as well as the Post Selling Services.

Automated sewing is a

complicated task in manufacturing. Due to the non-rigid work pieces and

variations in the material characteristics, sensor-based control has to

be used to accomplish the sewing operation. This paper presents a

strategy for velocity synchronization and corner matching in an

automated sewing cell based on two industrial manipulators and a sewing

machine. A hybrid force/motion control scheme is adopted using feedback

from force/torque sensors for tension control and optical sensors to

control the seam position. The strategy is based on switching between

force control and displacement control using a leader/follower

coordination scheme. This addresses the problem of corner mismatch

occurring when two independent force controllers are used for

controlling the two robots. Experiments verify that the proposed method

gives a satisfactory corner matching, which is crucial for the presented

sewing case.

The automation of sewing operations is a difcult taskin manufacturing. Several challenges arise from the non-rigidity and the large variations and uncertain material char-acteristics of the processed materials. This makes the designand implementation of both material handling and controlduring the sewing applications a complex task compared tohandling rigid materials. Nevertheless, there is a demandfrom the industry in high-cost countries to automate thesewing process.In the past decades, several research groups have workedin the eld of automated sewing and the handling of non-rigid materials.An automated sewing cell consisting of one robot and asewing machine is presented in. Both the tensionin the work piece and the seam allowance are controlled inreal-time.

Another sewing cell demonstrator based on a single robotand a sewing machine is presented in [6]. The task is to sewan assembly of two similarily shaped parts. A triangulation-based sensor is used for edge detection while optical motionsensors are used for measurement of the sewing speed.A demonstrator based on a sewing machine with a servo-controlled feeding mechanism is presented in [7]. Two parts,that are separated by a thin plate, are controlled indepen-dently by the servo mechanism. An open loop path controlis used which utilizes recognition of patterns on the fabric.The need for sensor-based feedback control is emphasizedby the authors.

No comments:

Post a Comment