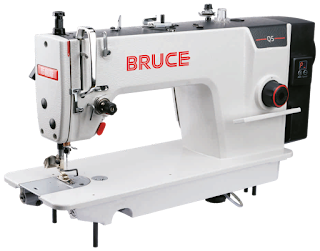

jack stitching machine in chennai, perambur, mylapore, madipakkam - VS SewingMachine

VS Sewing Machine, jack stitching machine in chennai, perambur, mylapore, madipakkam

offers you with the Top selling brands along with all its Sewing

Machines models in the Industry. You can get the recommendations over

here with the industry experts. Also we serves you best Pre-Selling as

well as the Post Selling Services.

This study describes some

possibilities of setting up an adaptive control method for an

electromagnetically actuated presser-foot in an industrial high-speed

sewing machine. The control of fabrics feeding in sewing machines is

difficult not only because of the complexity of relations between the

intervening variables (material properties, sewing speed), but also

because in many operations a varying number of material plies are

crossed. This implies that the reference for the controller has to be

adapted dynamically. Several methods, using PID and/or fuzzy logic

control, have been tried and are described in this paper. A preliminary

sewing test is able to provide data to tune the controller variables.

With these adaptation techniques, the machine would be able to

automatically adapt its feeding system according to the material being

sewn.jack tailoring machine in chennai, perambur, mylapore, madipakkam

The robotic handling of non-rigid objects, such as fabrics, is a very complicated problem since it is very difficult to model and predict the behavior of the fabric. The non-linearity, the large deformations and the very low bending resistance of the fabrics increase the complexity and difficulty of the robotic handling. In this paper, the robotized sewing is examined, where the fabric must be held taut and unwrinkled. Actually, a constant tensional force, which must be applied to the fabric throughout the feeding to the sewing machine, affects the seam’s quality to a great extent . Gershon clearly justified the need for force feedback control, in order to obtain a fabric’s constant tensional force in the sewing task.

While there is a big variety of force control methods on handling of rigid objects, the robotic research literature is not so rich concerning the handling of limp materials. jack f4 machine price in chennai, perambur, mylapore, madipakkam

In the FIGARO system, a PI controller is used, where the gains were chosen by trial and error. These gains should be modified when a new type of fabric should be handled. Gershon strongly suggested that the conventional control methods are inadequate to handle the fabric tensional force. An adaptive control approach was adopted by R. Patton et.al for controlling the tensional forces applied to a fabric, where the fabric’s stiffness was the unknown variable. They mentioned that non-adaptive control schemes are unsuitable for fabric handling due to high variations of fabrics’ stiffness. Koustoumpardis et al introduced an intelligent force control scheme based on a feedforward neural network (FNN) controller, using a force sensor mounted on the robots wrist.

No comments:

Post a Comment